Cultivation Techniques, news

Four tips to optimise the stability of your biofloc system

Biofloc veteran Dr Maurício Emerenciano, from CSIRO in Australia, shares four tips on how to optimise your biofloc system.

Experimental commercial-scale BFTs produced shrimp in Vietnam

These indoor setups were continuously tweaked for optimal water quality, enhanced shrimp yields and reliability © CSIRO

Our previous guide to biofloc technology revealed the many advantages of this culture system. New research allows us to better understand and further optimise biofloc production systems, leading to higher and more stable yields at an even smaller environmental cost.

First developed as a natural way to treat wastewater, biofloc technology systems (BFTs) have since become popular aquaculture production techniques, particularly in Asia. BFTs harness the nitrogen cycle to simultaneously treat culture water and provide farmed shrimp or fish with extra food, while offering a host of natural probiotic benefits.

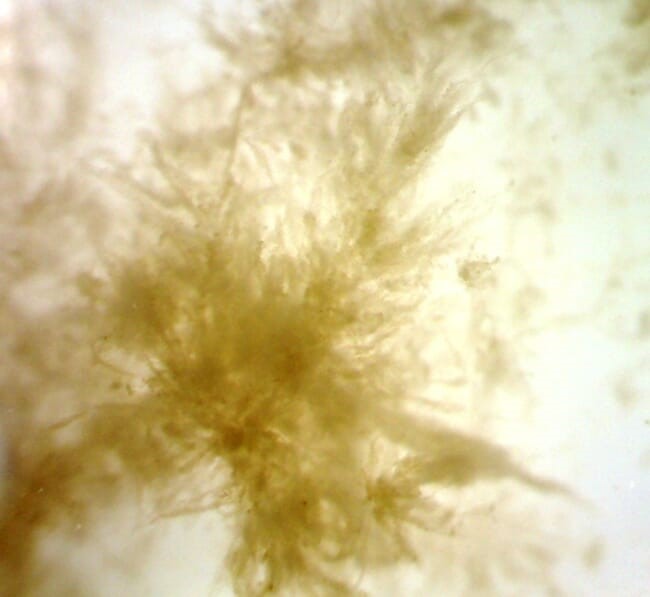

BFTs use algae, bacteria and other microorganisms to recycle waste nutrients and augment the growth of cultured stock. Various types of bacteria either break down toxic ammonia and nitrites into nitrates or assimilate ammonia into microbial biomass. Free-floating algae also help to improve water quality, while being eaten by zooplankton, fish and shrimp, these tiny microbes can also be populated in aggregate structures by an ever-growing host of organisms – including fungi, protozoans and other useful lifeforms. It is these floating masses are known as bioflocs.

Bound by bacterial slime, most of these floating aggregates are mainly microscopic, but larger aggregations can be seen by the human eye as brown or green suspended flakes. One of the main advantages of BFTs is that they require only certain nutrients and continuous aeration to provide a highly-functional culture habitat. Water supplements such as minerals and probiotics greatly help improve stability. BFTs can sometimes be less complex, in terms of infrastructure, compared to other super-intensive systems. BFTs also improve circularity in aquatic systems, are more ecologically-friendly and efficient, and can reduce the spread of deadly pathogens – making them a promising farming tool.

Close-up view of a microbial floc

One of the main advantages of BFTs is that they require only certain nutrients and continuous aeration to provide a highly-functional culture habitat. © Bill McGraw

New advances in biofloc research

Recent studies by Khanjani, Mohammadi and Emerenciano analysed the microorganisms associated with biofloc systems. The team found that BFTs contain a large variety of microorganisms – including microalgae, heterotrophic bacteria, nitrifying bacteria, fungi, ciliates, protozoans and edible zooplankton such as rotifers, copepods and nematodes. The presence and numbers of these useful microorganisms depend on a host of factors – including aeration, illumination, salinity, water quality and stocking density.

These tiny organisms generally perform three main functions:

- Improving water quality through bioaccumulation, bioassimilation, nitrification, denitrification and other ways of safely ridding culture water of nitrogenous compounds.

- Creating or enhancing probiotic properties of culture systems.

- Acting as a supplementary food source for the farmed stock.

BFTs work very well for raising shrimp and prawns

Using biofloc to raise shrimp or fish can reduce the feed requirements of farmed stock by 30 to 50 percent © CSIRO

A recent complementary study by Khanjani et al. assessed the nutritional value and functional properties of biofloc biomass and dry biofloc meal as a way to quantifiably augment aquaculture feeds. The study found that biofloc contains significant amounts of protein and lipids, which have the added bonus of being continuously available to culture stock. Probiotics and microbial derivatives can trigger immunostimulatory effects, reducing the feed requirements of farmed stock by an impressive 30 to 50 percent.

One of the principal authors of these two studies is Dr Maurício Emerenciano, who has been analysing and developing shrimp and fish production techniques, especially BFTs, for the past 15 years. In 2018, he joined the Commonwealth Scientific and Industrial Research Organisation (CSIRO) supporting aquaculture projects in Australia and Vietnam.

Aside from specialising in BFT, Dr Emerenciano is also a prolific writer, with over 130 published works in journals, magazines and books. From 2018 to 2021, he worked on BFT-based intensive production farms for shrimp in Vietnam. His team conducted a series of commercial-scale trial systems which produced high yields, including a consistent survival rate of over 90 percent and a maximum yield of 46 tonnes of shrimp per hectare per culture cycle.

BFT setup from the collaborative project between Viet-Uc and CSIRO

BFT operators need to constantly monitor water quality with reliable equipment to generate accurate and actionable data © CSIRO

He shares four tips to optimise the stability of your BFT:

1 Monitor and maintain your water quality

Your BFT requires optimal levels of alkalinity and dissolved oxygen to keep its population of microorganisms happy and productive. Vigilant monitoring of water quality using reliable equipment and methods is needed to generate accurate and actionable data. Proper data interpretation and consequent actions are crucial. This practice is not yet as common in regions like Southeast Asia and South America, where even long-time aquaculture practitioners often operate farms without fully comprehending the science behind them.

“The key to consistent performance is to generate reliable data using well-calibrated equipment, then acting swiftly and logically. Expensive technology is not mandatory, but reliable equipment is key. We still mostly do manual monitoring in our projects,” explains Dr Emerenciano. “Without reliable data and close monitoring, you might miss critical windows in which to take action. You’ll be surprised at the amount of misleading data you can find in the field. Especially at the start of the production cycle, it is imperative to monitor the curves of your N-compounds, alkalinity and Vibrio densities so you can take appropriate action when needed.”

2 Look after the system’s microbial community

Proper understanding of your BFT’s unseen but complex microbial dynamics is crucial to success. There are three communities that you need to balance: algae, heterotrophic bacteria and nitrifying bacteria.

As BFTs are constantly exposed to sunlight, they can quickly be overrun by algae. To control this, you can limit the available light to ensure a balanced and healthy population of heterotrophic bacteria.

A balanced heterotrophic-nitrifying community will effectively control your algal community. “You don’t want algal blooms in your BFT, as they can drastically lower oxygen levels at night, when these tiny plants stop photosynthesising. Also, when the population crashes, anaerobic sludge zones are formed rapidly, spreading pathogens,” notes Dr Emerenciano. For BFTs, algae are beneficial but should never dominate.

How do you create and maintain a stable heterotrophic-nitrifying community?

“Stable water quality parameters,” reveals Dr Emerenciano. “Monitor the development of your nitrifying community by noting N-compound peaks and trends, and quickly acting on the data.”

The nitrogen cycle is forever at work in your BFT. Stable levels of dissolved oxygen, pH, salinity and temperature helps your nitrifying community. In addition, proper alkalinity and suspended solid levels will help your desirable microbial population to thrive.

You can further promote the growth of your heterotroph community by closely managing your carbon-to-nitrogen ratio by infusing your culture system with external carbon sources as necessary.

.

The first steps to stocking a BFT pond

BFT practitioners need to create and maintain a stable heterotrophic-nitrifying bacterial community in their ponds

“There is a myth that external carbon sources will harm your BFT culture. An oversupply might more likely be the trigger. The difference between a poison and a medicine is often the dosage”. This is true for BFTs and one that lots of scientific publications have already demonstrated. Again, microbial understanding is key. C:N ratios are crucial. You can check out our previous article for more practical tips on this topic.

“In our systems, we add external carbon sources (eg sugar cane molasses) as a management tool when needed. This fosters the growth of heterotrophs, thereby keeping the water stable to suppress algal blooms,” notes Dr Emerenciano.

You can also use commercial strains from trusted brands (known as aquatic -and not terrestrial- probiotics) to make sure you are growing the right communities of the most effective species.

“Always go for quality products to maximise your chances of good results. You also need nitrifying bacteria which grow slowly and have a slower metabolism. Again, proper alkalinity and dissolved oxygen levels are key to ensure the proper growth of these mandatory communities,” he explains.

3 Proper waste and feed management

As there is limited water exchange in any BFT, you must continuously monitor and manage both waste and water quality. Waste can be minimised by properly-tuned autofeeders and high-quality feeds, which generate more stock growth through better digestibility. This in turn creates less waste.

Shrimp raised in a biofloc system

Since BFTs rely on limited water exchange, operators must continuously monitor waste levels and water quality parameters

“Although high-quality feeds are more expensive, the final outcome in your production will be much better,” Dr Emerenciano reflects.

You should also employ the right feeding strategies and never overfeed.

“Based on the results of your water quality monitoring, you should adjust the amount of feed. As nitrogen peaks or as temperatures decrease – you should decrease your feeding accordingly and accurately,” Dr Emerenciano continues.

Poor quality feeds, an excess of carbon sources or overfeeding will increase the sludge load and pathogen spread in your system. Dissolved oxygen, pH and other parameters such as ammonia, nitrite and Vibrio loads will also be affected. Sludge accumulation is a powerful trigger to unbalance your system and a perfect recipe for a disaster,” he emphasises.

Everything in a BFT exists in balance. Rocking the boat can be dangerous. The spread of pathogens is often directly linked to improper water quality, feeding and waste management. To keep abreast of culture conditions, keep checking your culture parameters and properly interpret them.

A sample of biofloc culture water

The spread of pathogens in a BFT is often directly linked to improper water quality, feeding and waste management © Bill McGraw

4 Use the right engineering and tools

For your BFT to succeed, you need to have the right infrastructure in place.

“Proper aeration, sludge removal and efficient drain design is crucial. You will need a suitable number of diffusers, with good water movement and oxygenation. Simple technology is fine, but keep your systems clean and well-maintained to ensure that everything operates at peak efficiency,” Dr Emerenciano observes.

Future developments

The future of BFT looks bright, but there are still many gaps which the industry and new researchers can fill. Meanwhile, decision supporting tools using artificial intelligence, linked and connected to automatic feeders, water quality sensors and cloud-based data systems will make operation reaction times quicker, Dr Emerenciano argues.

“You’ll notice that I keep emphasising continuous monitoring, which can really optimise your reaction time and input requirements. We should embrace technology as much as young or tech-savvy aquaculture operators, who can now complete a surprising number of tasks on their mobile phones. I think we shall see the real revolution in automated and digital aquaculture within a decade,” Dr Emerenciano continues.

Developing green culture systems for tomorrow.

Mauricio and the CSIRO and Viet-Uc teams during their research activities © CSIRO

“New thermo storage technologies and the reliance on cost-effective renewable sources of clean energy – such as solar, small-scale hydro and wind power – will also be a challenge over the next decade. Some technologies can reduce the carbon footprint not just of BFTs, but all our future aquaculture operations,” he adds.

Another important aspect is proper waste disposal, particularly in developing countries where natural systems are relatively rich, but often threatened by poorly-curbed development and pollution. The improper treatment and disposal of waste can trigger pathogen outbreaks. We are seeing this scenario over and over again. The continuous battle with AHPND/EMS in Southeast Asia is a perfect example. Crossing your farm gate, routine pathogen surveillance is mandatory and will help guide your decisions.

Keeping abreast of new developments and technologies will ensure steady seafood yields tomorrow. In the exciting field of biofloc technology, reduced feed requirements, clean and microbe-rich water, probiotic benefits and greener stock production at comparable costs can be realistically achieved once proper management techniques are followed. No wonder more and more aquaculture operators are flocking to this system.

By The Fish Site

Reference: https://thefishsite.com/articles/four-tips-to-optimise-the-stability-of-your-biofloc-system

See more:

- What aquaculture producers can use instead of antibiotics

- AI Chatbots and Aquaculture Professionalism

- QR Codes: innovative branding initiative to enhance Bangladesh’s shrimp industry

Tiếng Việt

Tiếng Việt