Cultivation Techniques, news

Utilization of Shrimp Shell Waste as Alternative Raw for Mariculture

Abstract.

Feed is still one of the problems in aquaculture because it takes about 70% of operational costs. High prices is caused by imported raw materials for feed production. One possible effort to overcome this problem is to find alternative local raw materials to replace imported fish meal. The purpose of this study was to examine the proximate content of shrimp shell wastes from processing shrimp crackers (Paneus sp.) to be used as shrimp flour. Samples were colledted three times in a month, at the beginning, middle and end of the month. The waste of the heads, shells and tails of the shrimp were turned into flour for laboratory testing through proximate analysis. The data were tabulated using the Microsoft Excel softwareand then analyzed descriptively by comparing the nutrient content of shrimp waste flour with the feed requirements of mariculture. The results showed that shrimp shell flour contained protein, fat, carbohydrates and ash content of around 27.4%, 2.07%, 14.84% and 47.27%. while the resulting randemen ranged from 81.75%. Therefore, shrimp shell flour can be used as an alternative raw material for preparing marine fish feed.

Introduction

Shrimp is one of the largest export commodities in Indonesia. Since September 2018, the value of Indonesia’s shrimp exports has reached 147,164,696.07 kg or equivalent to 1,302,330,215.54 USD. Kepulauan Riau province contributed 18,517 tons of shrimp from the capture fisheries sector and included Lingga Regency (KKP, 2018) [6]. Not only being consumed in raw form, shrimp has also entered the processing industry. This commodity can be served in various forms such as shrimp packaged whole from the body and head, headless shrimp body, shrimp meat only, and prawn crackers.

The proces of turning shrimp into prawn crackers only utilizes the flesh of the shrimp while the heads, shells, and tails of the shrimp are thrown away and are not used. Waste from this process can reach 35-50% of the shrimp weight. Muzzarelli and Joles (2000) [8] reported that shrimp waste still contains around 25-40% crude protein. One of the ways to use shrimp shell waste is by processing it into shrimp flour. Shrimp flour is expected to play a role in replacing fish meal in the preparation of aquaculture feed rations. The use of local raw materials as an alternative fish meal needs greater attentions.

The nutritional content, especially the protein from this material, is adequate to meet the needs of the cultured organisms. The alternative feed can be a possible solution to reduce feed production costs and increase cultivation yields. So far, almost 90% of the circulating feed for fish farming activities is supplied from the industry in which the manufacturing process still relies on imported raw materials thus it leads to the difficulties in maintaining stable feed prices (Rohmanto, 2017) [13]. This study aims to examine the proximate content of shrimp shell waste from processing shrimp crackers (Paneus sp.) and turning it into shrimp flour. The flour is expected to be an alternative raw material in the formulation of artificial feed for marine fish farming activities. Therefore, by reducing the use of imported fish meal, the production costs can be more affordable.

Method

This research was carried out in April-August 2021. The samples are the head, shell and tail waste of shrimp (Paneaus sp.) and were collected from shrimp crackers processing factory in Sungai Buluh Village, Singkep Barat District, Lingga Regency. The flouring process was conducted in the Laboratory of the Faculty of Marine and Fisheries Sciences, Universitas Maritim Raja Ali Haji. Meanwhile, the proximate test was conducted in the Saraswanti Indo Genetech Laboratory, Bogor. Samples were collected three times in a month namely at the beginning, middle and end of the month. Later, the samples consisting of the heads, shells and tails of the shrimp were turned into flour for laboratory testing with proximate analysis. The data taken from the proximate test result were tabulated with the Microsoft Excel program. Further, the data were analysed descriptively by comparing the nutrient content of shrimp waste flour with the feed requirements of mariculture.

Result

Nutrient Content

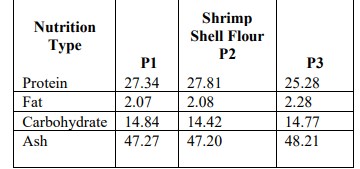

The nutrients contained in shrimp shell flour is displyed in table 1:

Table 1. Results of the proximate analysis of shrimp shell flour (Peneaus sp.)

Description: Data in % dry weight

The Value of Shrimp Shell Randement

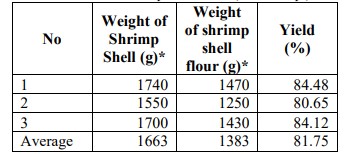

The value of the largest proportion is the meat that reaches 50% and 50% of the skin is wet. The yields producing shrimp shell flour can be seen in table 2 below.

Table 2. Randement Shrimp Shell Flour (Peneaus sp.)

The proportions of meat and shrimp shells are comparable in this study namely 50%:50%. The shrimp shell waste was not separated into parts since it was considered to maximize its utilization. This proportion is higher than Diah (2011) [5] who stated that the proportion value per shrimp is 36-58% meat, respectively 29-41% head and 13-23% skin. These results indicate that 50% of the total weight is considered as waste in the shrimp production. Therefore, it is necessary to manage the shrimp.

Discussion

Protein is needed by fish as a source of essential amino acids to support optimum growth, repair damaged body tissues, maintenance of body protein, addition of body protein for growth and as a source of energy (Furuichi, 1988) [5]. Fish cannot produce protein from their own bodies so it is absolutely necessary to supply them through the feed. The nutritional value of protein in shrimp shell flour is 27.34%. The protein content is lower when compared to other raw materials. Widaksi, dkk (2014) [17] reported that the protein of fish meal, bone meal and soybean meal were 31.55%, 35.15% and 30.55%.

The low protein in shrimp shell flour is possibly caused by differences in the handling of shrimp shell waste. Olivia, et al., (2013) [13] reported that the protein content of shrimp shell flour produced was lower due to the process of soaking the shrimp shells which impacted a reduction in protein content. Proteins are composed of globular proteins that have water-soluble properties (Triyono, 2010) [18]. The required protein for fish depends on the age of the fish, the size of the fish, the temperature of the water and their eating habits. Seawater fish with carnivorous habits requires protein by >40%. Meanwhile, omnivorous fish requires 30-40% protein in the feed, and herbivorous fish requires a fairly low protein ranging from 20-30% in feed. Therefore, the shrimp shell flour from this study can be used as a protein source in the preparation of fish feed rations for herbivorous fish.

Fat is a source of energy in fish which contains two times higher energy compared to the energy produced from protein and carbohydrates. 1 gram of fat is equivalent to 9 kcal of energy produced. Fat also functions as a transport medium for several compounds in the body such as fat-soluble vitamins and hormones. Fat is also a source of metabolic energy for reproduction. The fat contained in the shrimp shell flour is 2.07%. Peneaus monodon in the post larval and juvenile stages requires 2% and 1.25% fat in feed (Chen, 1992) [4]. Thus, this need can be met by adding shrimp shell flour in the feed. The fat content in the feed should not be too high. This may lead to the accumulation of fat in the visceral cavity and body tissues (NRC, 1993) [11].

Carbohydrate is an easy-to-get source of energy for fish. Carbohydrate plays a role in the formation of the carbon skeleton of non-essential fatty acids and also in fat synthesis. In addition, carbohydrate is also important in the formation of oxaloacetate and NADPH2. The amount of carbohydrates that can be utilized and is good for the growth of carnivorous fish are 10-20%. The ability of fish to utilize carbohydrates as a source of energy relies on their enzymatic capacity to secrete amylase. The greatest enzyme activity was found in herbivorous fish, then omnivores and finally carnivores. Thus, herbivorous and omnivorous fish can utilize carbohydrates as an energy source better than carnivorous fish (Guillaune et al., 2001) [7].

The carbohydrate content in shrimp shell flour is 14.84%. This content is in accordance with the carbohydrate requirements of carnivorous fish. Carnivorous fish requires carbohydrates in the range of 10-20% in feed (Furuichi, 1988) [6]. Although it has low ability to use it, carbohydrates must be available in fish feed because the lack of carbohydrates impacts other nutrients such as protein and fat will be metabolized as energy and fish growth will be slow (Handayani, 2006) [8]. Feeds containing the right carbohydrates and fats can reduce the use of protein as an energy source known as the Protein Sparring Effect. The existence of Protein Sparring Effect can reduce the cost of feed production and reduce the expenditure of nitrogen waste into the environment. Feeds containing high carbohydrates have been reported to lead to fat accumulation in the liver in 2 E3S Web of Conferences 324, 03006 (2021) https://doi.org/10.1051/e3sconf/202132403006 MaCiFIC 2021 juvenile carp (Kurniasih, dkk, 2015) [11]. The same thing was also reported in red sea bream. Carbohydrates can serve as precursors for amino acids and nucleic acids, and metabolic intermediates necessary for growth (Craig and Helfrid, 2002). Ash contents suggest the total minerals in a material. Minerals are components of feed that are needed by the body namely as forming the body structure (skeleton), maintaining the colloid system (osmotic pressure, viscosity) and regulating acid-base balance. Moreover, minerals are also important components of hormones and enzyme activators (cofactors) (NRC, 1993).

Minerals needs in fish depend on the type of fishs, stadia, reproductive status, and the environment and the ability of the fish to absorb minerals from their environment. Actually, fish have the ability to absorb minerals from the water (its environment) but the amount is not sufficient. Therefore, it is absolutely necessary to add it to the feed. In the preparation of artificial feed, mineral mix is usually added in the range of 2-5% of the total amount of feed raw materials (Gusrina, 2008) [8].

The ash content in shrimp shell flour showed the highest value compared to other nutrients which was 47.27%. The ash content is obtained from the structure of the shrimp shell which consists of chitin, calcium carbonate. Thus, shrimp shell flour can be used as a source of minerals in the preparation of fish feed rations. In addition, all of these components can be isolated or extracted so that they have a higher selling value compared to shrimp shells (Rao et al., 2000) [19]. The treatment is to make shrimp flour from the shrimp shell waste so it can be used as raw material in the manufacture of fish feed.

Based on the data in the table above, the average value of the resulting randemen is 81.75%. The resulting yield value decreased from the number of shrimp shells. The reason of this is that the sample size is getting smaller causing losses during the particle size reduction (refining) process. The yield value obtained in this study was higher than the yield value obtained by (Pratiwi, et al., 2017) [17] which only produced an average yield of around 15.95%. The process of reducing the particle size (refining) is undertaken to turn the shripm shells into flour.

Furthermore, the flour made is easier to be mixed with other ingredients in the process of making fish feed. In addition, in the refining process, the resulting flour has decreased water content allowing it to be stored for a relatively longer period of time. The result of shrimp shell flour is slightly brownish in color. This red color is due to the shrimp shell containing a naturally occurring red pigment (astaxanthin). During the drying and grinding process, the shrimp skin turns dark and slightly brown. This happens because of the reaction between the protein and carbohydrate content in the shrimp shell with heat (temperature).

Conclusion

Dealing with the result of the study, it can be concluded that the nutritional content of shrimp shell flour consisted of protein, fat, carbohydrate and ash content of 27.4%, 2.07%, 14.84% and 47.27%, respectively. The result of randemen was around 81.75%. There is a need for further research on improving the quality of raw material for shrimp shell flour.

By Tri Yulianto, Dwi Septiani Putri, Shavika Miranti, Wiwin Kusuma Atmaja Putra

Tiếng Việt

Tiếng Việt